Precision - Made in Germany

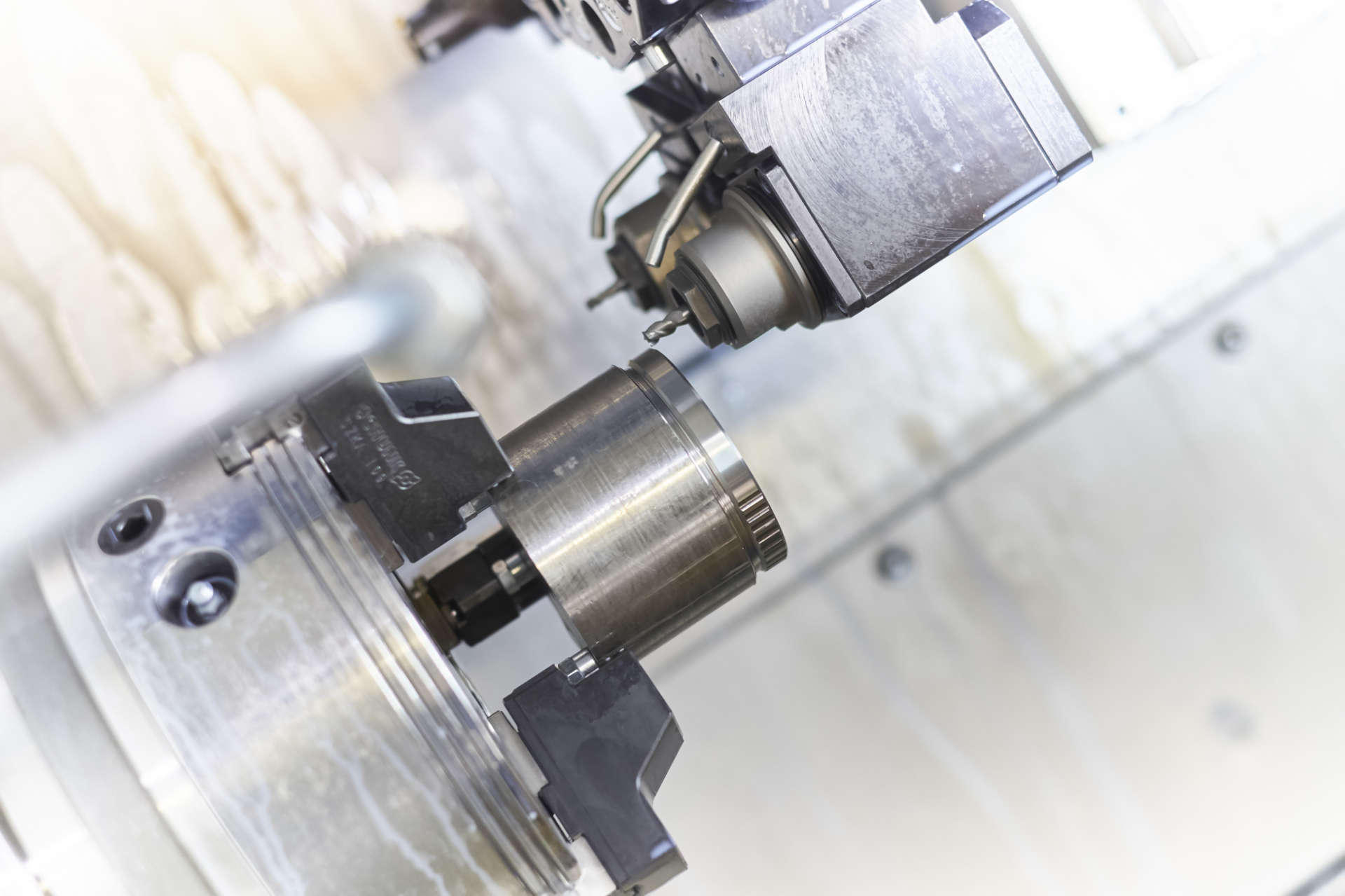

In addition to the development and production of original NOVOFLEX® products, we also offer customized manufacturing solutions for many other premium brands. With our modern machinery, designed for the highest precision, we manufacture even the most demanding components and products in-house. We offer CNC turning, milling, glass bead blasting, vibratory grinding, painting, and laser engraving. Our contract manufacturing clients primarily come from the fields of film and photography, optical industries, automotive, electrical industries, and mechanical engineering.

Our Offer for Industrial Clients

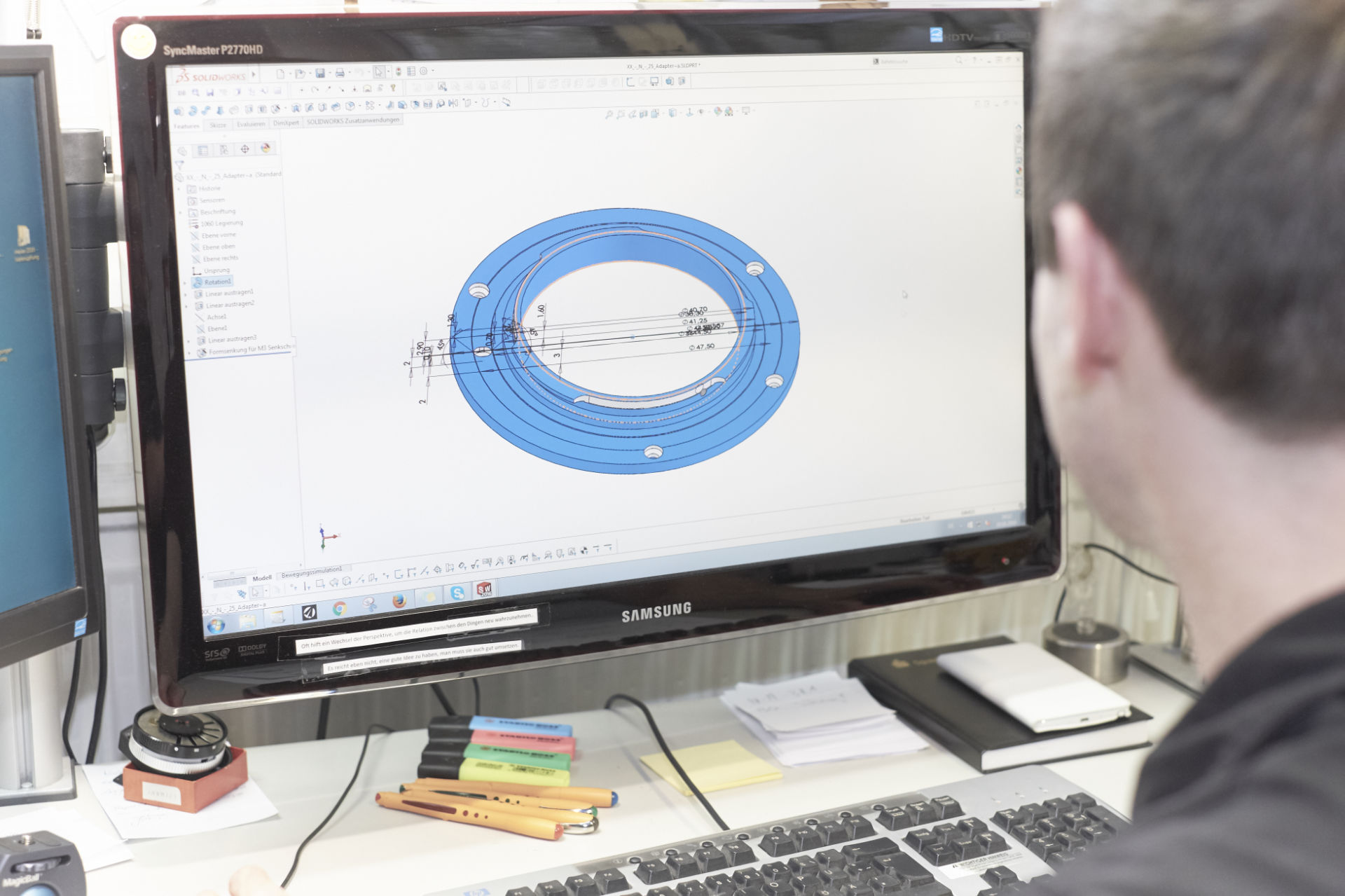

We provide a complete solution – from development and prototype manufacturing, including practical testing, to series production of components, modules, or complete products.

Our services include:

- Precise CAD design

- CNC turning and milling parts, according to your drawings or patterns – including post-processing (Anodizing, Bluing, Brushing, Chrome Plating, Galvanizing, Grinding, Hard Anodizing, Lacquering, Laser Enraving, Polishing, Powder Coating)

- CNC turning parts: from bar up to Ø65 mm (Index G200), from chuck up to Ø150 mm (CTX alpha 500)

- CNC milling parts: component length up to 850 mm (DMC 850V and DMC 635V)

- Assembly work

- Ideal batch sizes from 5 to 2,000 pieces

Do you have any questions or would you like to request a customized solution? Simply fill out the form below, and our team will get in touch with you promptly to discuss your requirements and develop a tailored solution for your production.

Your Inquiry